Subtotal:

229,168৳

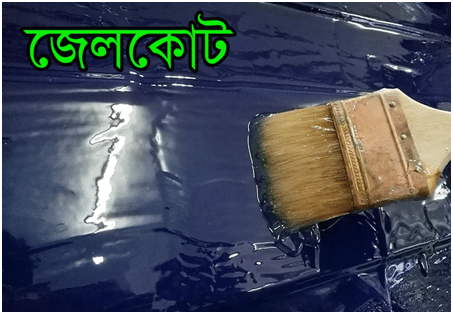

Gelcoat, Fiberglass Gelcoat

450৳ – 8,200৳ (-9%)

- Make a smooth surface with a liquid gelcoat.

- Any fiberglass product can create a smooth surface.

- Any of the sculptures, furniture, speed, boats, artificial birds, swimming pools, car

and bike bodies, plastic, tins and park rides It takes a gel coat to create a

smooth surface. - Very Shine and Nice Colors

- Wide Application

- Cure at room temperatur

Category: Gelcoat

Usage: Manufacture of high-quality surface lamination FRP composite tooling.

Description: Gel coat features good strength, hardness, tenacity, low shrinkage,

excellent waterproof, heat resistance, wear resistance, good weather ability, and

finished FRP product with good transparency, suitable for hand layup process FRP

model surface protection layer. Gelcoat is a resin system that is filled with colorants and

thickening agents and applied to a mold surface to form the cosmetic and weathering

coating of a composite part. Gel coat is typically the first layer of a part to be applied.

Correct application of gelcoat is critical to get the optimum performance from it.

Gelcoats are based on a thermoset resin that requires an initiator and proper

temperatures to cure thoroughly. Incomplete cure will result in poor durability of the

gelcoat. This is often witnessed as premature fading, dulling of the gelcoat surface, or

chalking. There are 3 variables that affect proper cure: temperature, film thickness, and

initiator level.

Temperatures should be between 60-80 degrees F. with an optimum

range being between 70-75F. We like to use an infrared thermometer to check the

temperature of the mold surface and gelcoat. We use the infrared and a wall

thermometer to check the ambient temperature of the workspace.

Keep in mind that molds stored in areas that are not climate controlled may not reach room temperature

for quite some time. Gelcoat should be initiated (catalyzed) to set up to the point that

you can touch it with a glove and not have it come up on your finger in 45-60 minutes

from application.

Generally speaking and depending on the temperature a catalyst ratio

of between 1.2% to 3% will give you the proper cure rate. At 77F 1.8% MEKP will

provide a gel time of 10-17 minutes. Keeping good notes will help you build a database

of initiator levels for temperatures that you encounter frequently. Gelcoat that is

over-initiated can result in excessive shrinking and premature release from the mold.

Tags: Gelcoat Price in Dhaka Bangladesh, Polyester

resin, FRP, Hardener, MEKP, Catalyst, Fiberglass, Mold Making.

Video link: https://youtu.be/EFz7B705o2Y

Additional information

| color | Translucent |

|---|---|

| weight | 10Kg, 1kg, 5 kg, 20kg |

Reviews

There are no reviews yet.